Get Professional Help

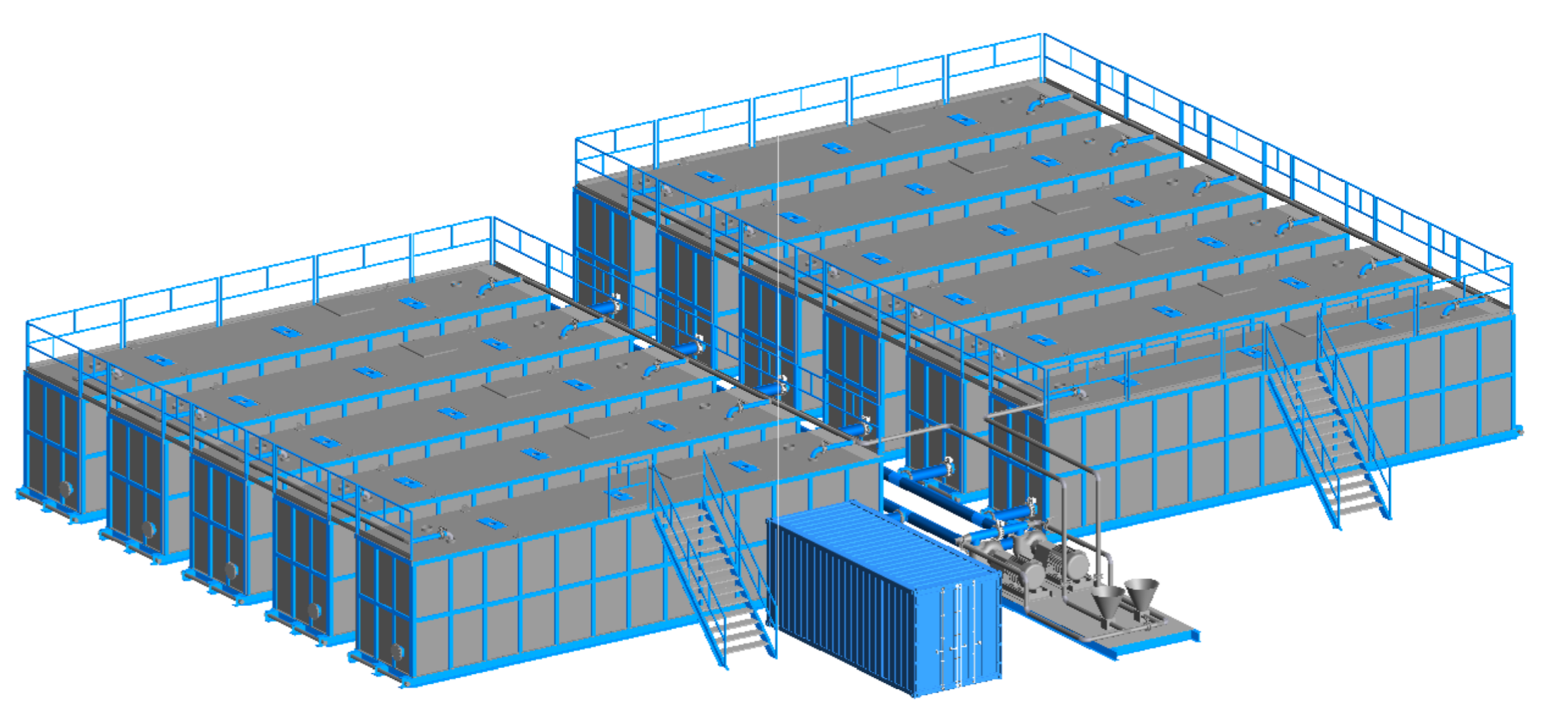

MUD PLANT AND TANK FABRICATION

The primary purpose of a Liquid Mud Plant is to maintain optimal drilling mud properties within the wellbore. At drilling fluids supply bases drilling companies manage and manipulate various drilling fluids for use in wells associated with the supply base. Additionally, these facilities often include expanded drilling waste management (DWM) and solids control processing, typically employing decanter centrifuges to treat used mud that has been returned to the supply base. Offshore supply vessels are utilized for transporting drilling and completion fluids to and from the Liquid Mud Plant, especially when mixing or treatment cannot be performed on-site.

Types of tanks commonly found in a Liquid Mud Plant include:

- Oil-Based Mud Tank

- Water-Based Mud Tank

- Base Oil Tank

- Water Tank

- Brine Tank (constructed with Fiber Glass or Coating protection)

- Bulk Tank

- Mud Mixing Tank

The equipment employed in a Liquid Mud Plant typically includes a decanter centrifuge for solids control in drilling mud. In some cases, clients may request a shale shaker for the removal of coarse solids. Mud agitators are strategically placed on mud storage or mixing tanks to prevent solids from settling in the fluids. Mud guns, especially in the corners of the mud tank, may also be used for agitation. Mud mixing and chemical addition are accomplished through Mud Mixing Hoppers and centrifugal pumps.